Product Description:

Sintered Ferrite Magnet Product Summary:

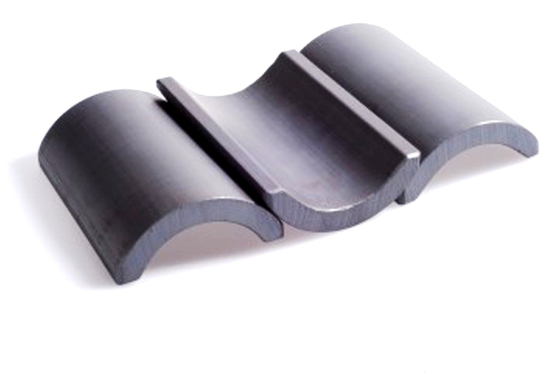

The Sintered Ferrite Magnet is a high-quality magnetic product designed to provide reliable performance in various applications. With a maximum operating temperature of 250°C, this magnet is suitable for use in environments where elevated temperatures are present.

Available in multiple model numbers including JC-Y3932, JC-Y4127, and JC-Y4231, this magnet offers versatility to meet different requirements. The dimensions of the magnet can be customized to suit specific needs, ensuring a perfect fit for your application.

Hailing from Sichuan, China (Mainland), the Sintered Ferrite Magnet combines quality craftsmanship with durable materials to deliver long-lasting performance. Its origin in a reputable manufacturing location underscores the product's reliability and consistency.

The size of the magnet is (R53.4mm-r48.4mm)*52mm, providing ample magnetic strength within a compact form factor. Whether used in industrial machinery, electronic devices, or automotive components, this magnet offers strong magnetic properties to support various functions.

With its robust construction and efficient magnetic properties, the Sintered Ferrite Magnet is an ideal choice for applications that require dependable magnetic performance. From medical equipment to industrial machinery, this magnet can enhance the functionality of products such as the Medical Nasal Suction Cutter Shaver System Surgical Power Drill.

Invest in the Sintered Ferrite Magnet for reliable magnetic solutions that excel in demanding environments. Enhance the performance of your products with this versatile and durable magnet, designed to meet the needs of various industries.

Features:

-

Product Name: Sintered Ferrite Magnet

-

Origin: Sichuan, China (Mainland)

-

Max Operating Temperature: 250°C

-

Composition: Ferrite Magnet

-

Model No: JC-Y3932, JC-Y4127, JC-Y4231

-

Dimension: As Customized

Applications:

Sintered Ferrite Magnets are a versatile product with a wide range of application occasions and scenarios due to their unique attributes. Composed of Ferrite Magnet material, these magnets can withstand a maximum operating temperature of 250°C, making them suitable for various demanding environments.

The block shape of Sintered Ferrite Magnets allows for easy customization of dimensions, catering to specific requirements across different industries. One of the key application scenarios for these magnets is in the medical field, particularly in devices such as the Medical Nasal Suction Cutter, Shaver System, and Surgical Power Drill.

When used in medical equipment like the Nasal Suction Cutter, Sintered Ferrite Magnets provide reliable magnetic properties that aid in the precise functioning of the device. The magnets' high temperature tolerance ensures they can withstand the sterilization processes required in medical settings, maintaining their performance over time.

In the case of the Shaver System, the block shape of the Ferrite Magnets allows for compact designs while offering strong magnetic force, enhancing the efficiency of the system. Similarly, in Surgical Power Drills, these magnets play a crucial role in providing the necessary magnetic power for precise and controlled drilling operations.

With the ability to customize the dimensions of Sintered Ferrite Magnets, manufacturers can tailor these magnets to fit specific components within medical devices, ensuring optimal performance and reliability. Their durability and stability at high temperatures make them a preferred choice for critical applications in the medical field.

In conclusion, the Sintered Ferrite Magnets are ideal for a wide range of applications, including the Medical Nasal Suction Cutter, Shaver System, and Surgical Power Drill due to their composition, high operating temperature, block shape, and customizable dimensions.

Customization:

Product Customization Services for the Sintered Ferrite Magnet:

Composition: Ferrite Magnet

Size: (R53.4mm-r48.4mm)*52mm

Origin: Sichuan, China (Mainland)

Max Operating Temperature: 250°C

Shape: Block

Support and Services:

Our Product Technical Support and Services for the Sintered Ferrite Magnet include:

- Expert assistance with product installation and troubleshooting

- Recommendations for optimal usage and maintenance

- Access to comprehensive product documentation and resources

- Training and guidance on product features and capabilities

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!