Injection molded magnets are manufactured by injecting special pellets into a mold. This magnet has the extensive properties of a bonded magnet, including heat resistance. Injection molding technology offers flexibility in shape design, as well as overmolding and insert molding with other parts for easy assembly.

Advantages of Injection Molded Magnets

With this isotropic magnet, any magnetization direction can be applied. This is an inherent advantage of making multi-pole magnets.

Injection molded magnets have excellent dimensional accuracy and mass production capacity.

Thin wall thicknesses and complex shapes can be fabricated.

Overmolding and insert molding with other parts such as back yokes, hubs, axles is readily available, and injection of other polymer parts can also be added.

The volume fraction of polyester binder for injection molded magnets is higher than for compression molded magnets. In most applications it will provide adequate corrosion protection without coating.

| Magnet info |

| Materials |

Ferrite |

| Type |

Permanent, Injection Ferrite Magnet |

| Shapes |

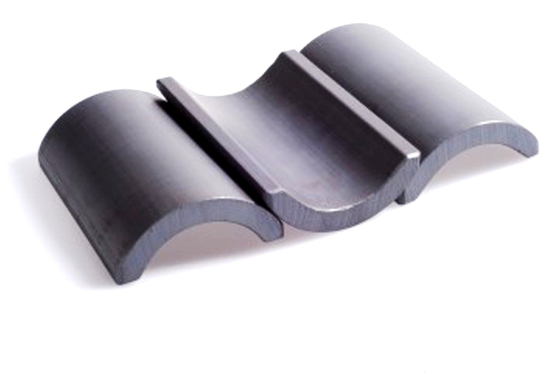

Magnet Tile, Arc, Tile, other according to your requirements |

| Size |

Length x Width x Thickness You could choose freely according to your plan. |

| Certificate |

IATF 16949 |

| Quality |

Our expert quality control department ensures magnets are high quality. |

| Applications |

Household application, Industrial application…. |

Ferrite Magnets' outstanding properties

1) High performance:

JC-Y3932; JC-Y3939; JC-Y4041; JC-Y4127; JC-Y4231; JC-Y3744; JC-Y3849; JC-Y4240 JC-Y4350 etc (The grade like JC-Y4350&JC-Y3849, JC-Y4240could meet requirements on strong power).

2) High working temperature:

The JC-Y4350 series with 4800-5150 Oe super-high coercive force can replace NdFeB magnets with much lower price.

3) High consistency:

The Br and Hcj of surface magnetic field and magnetic flux can be controlled with +/-1%.

4) High Anti-corrosion:

The sale spray test and humid heat test of the high anti-corrosion coating could be more than 800 hours

5) Low weight loss

The average low weight loss is less than 10 mg/cm2 in 20 days.

Pros: Pretty strong hold between two of these blocks even if a couple of them by contacting the other one or plain iron. It's difficult to pull away them(easy to slide however).

|

GRADE

|

Br

|

Hcb

|

Hcj

|

(BH)max

|

|

T

|

Gs

|

KA/m

|

Oe

|

KA/m

|

Oe

|

KJ/m3

|

MGOe

|

|

JC-Y3932

|

0.375-0.400

|

3750-4000

|

230-275

|

2890-3456

|

235-290

|

2950-3645

|

26.5-31.5

|

3.33-3.96

|

|

JC-Y3939

|

0.380-0.400

|

3800-4000

|

255-290

|

3200-3645

|

260-325

|

3260-4080

|

26.5-31.8

|

3.33-4.00

|

|

JC-Y4041

|

0.390-0.415

|

3900-4150

|

260-300

|

3260-3770

|

300-350

|

3770-4400

|

27.0-32.0

|

3.39-4.02

|

|

JC-Y4127

|

0.400-0.420

|

4000-4200

|

180-225

|

2260-2825

|

185-228

|

2320-2865

|

30.0-33.6

|

3.77-4.22

|

|

JC-Y4231

|

0.410-0.430

|

4100-4300

|

220-260

|

2765-3265

|

255-270

|

2825-3390

|

31.5-35.5

|

3.95-4.46

|

|

JC-Y3849

|

0.370-0.400

|

3700-4000

|

271-305

|

3405-3830

|

370-400

|

4650-5025

|

26.0-31.2

|

3.27-3.92

|

|

JC-Y4240

|

0.410-0.430

|

4100-4300

|

285-314

|

3580-3945

|

306-340

|

3845-4270

|

31.5-34.4

|

3.95-4.32

|

|

JC-Y4545

|

0.440-0.460

|

4400-4600

|

310-354

|

3895-4445

|

346-375

|

4350-4710

|

36.5-39.5

|

4.59-4.96

|

|

JC-Y4350

|

0.420-0.440

|

4200-4400

|

295-325

|

3700-4080

|

382-410

|

4800-5150

|

33.5-36.5

|

4.21-4.59

|

Packaging & Delivery

Packaging Details: Carton Wood Pallet

Special Package according to your requirements

Delivery Detail: 10 -40 dyas or according to the order

Company Introduction:

Our company is certificated by ISO/TS 16949: 2002 quality system, meanwhile we are a member organization of National Standarlized Technical Committee of magnetic components and ferrite materials, joint-mag is leading the development of the industry and has become one of the most powerful professional manufacturers of permanent ferrite products through continuous technological progress and equipment upgrade.

Sincerely welcome to visit our factory.

Samples are available for your test.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!